Due to its bio-based nature and biodegradability, polybutylene succinate (PBS) is a sustainable alternative to conventional polyolefins, which can be persistent in the environment due to their long degradation time. The LoopPBS project is the first to demonstrate a new type of chemical recycling of PBS and the processing of this recycled PBS (rPBS).

Technical demand:

- Thermo-mechanical damage to the molecular chain structure of polymers

- Mixed fractions despite the same type of plastic

- Only a limited proportion of recyclate can be used

Scientific-technical solution:

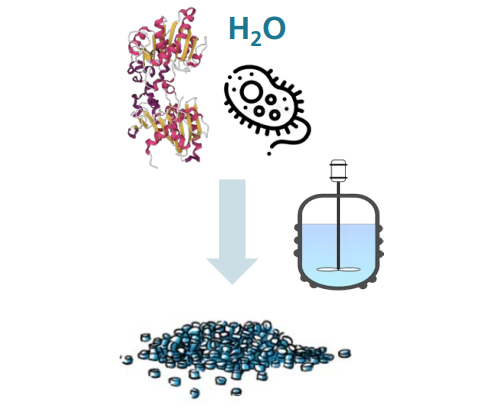

- Hydrolysis process + enzymatic / microbial depolymerisation into monomers

- Demonstration of the re-synthesis of rPBS

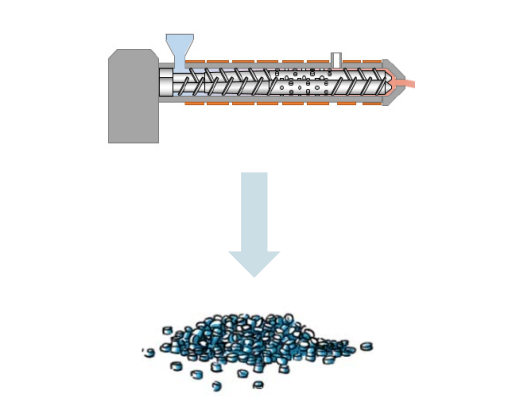

- Industrial processing of rPBS